CDL SERIES

VERTICAL MULTI-STAGE CENTRIFUGAL PUMP

.jpg)

.jpg)

CDL SERIES

-

CDL pump is a vertical multistage centrifugal pump that pipeline structure can ensure the pump is directly installed in the pipeline system with the same pipe diameter and same outlet and inlet at the same level. This structure design makes the connection from the pump to the pipe more compact.

-

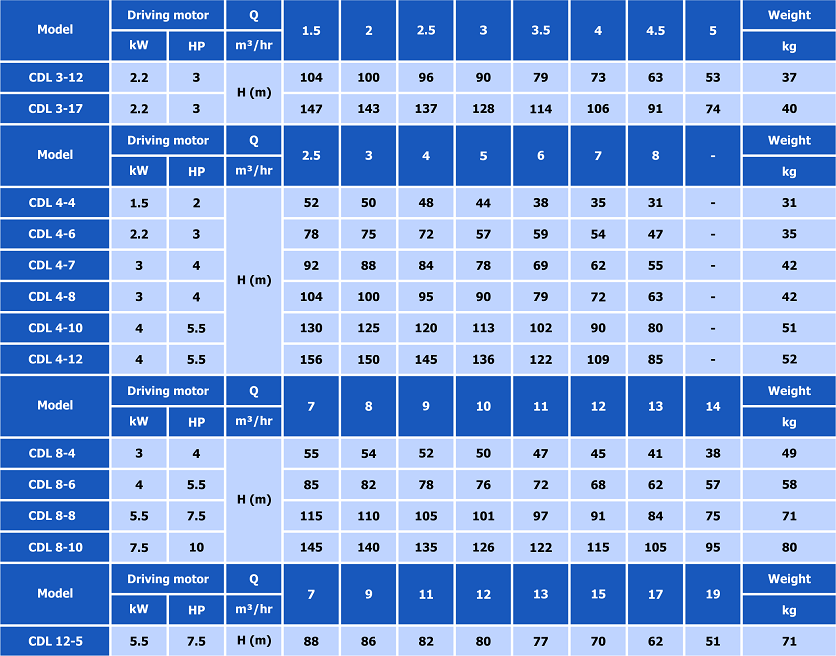

CDL pumps have different specifications and series to meet the flow rate and pressure requirement.

-

A kind of multi-functional pump that can transfer not only water but also various industrial liquid medium, suitable for different temperatures, flow rates, and pressure ranges.

Typical Applications:

-

Water supply: Water filtering and conveying, water partition, net pressure boosting for high-rise buildings, hotels, industrial water pressure boosting.

-

Industrial boosting: Process water system, cleaning system, high-pressure washing system, fire fighting system, and car cleaning.

-

Industrial liquid transportation: Cooling and air-conditioning system, boiler feedwater system, and temperature system.

-

Delivery: Oil and alcohol, acid and alkali, ethylene glycol, and coolant.

-

Water treatment: UF, R.O. system, distillation systems, separator, and swimming pool.

-

Irrigation: Region irrigation, sprinkler irrigation, and drip irrigation.

Motor

-

Full-enclosed air-blast two-pole standard motor.

-

Protection class: IP55

-

Insulation class: F

-

Frequency: 60Hz

-

Standard voltage:

-

3x220-230/346-400V

-

3x220-255/380-440V

-

3x220-227/380-480V

-

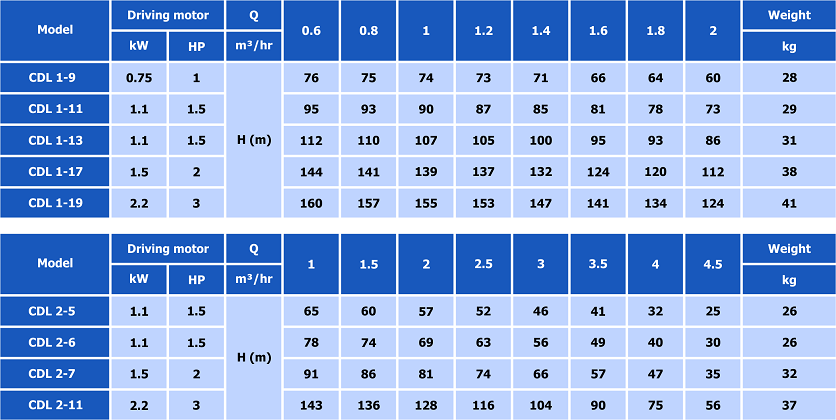

Single performance curve

-

All measure values of curves are based on the motor at a constant speed of 2900 RPM and 2950 RPM.

-

Curve tolerance meets ISO9906, Appendix A.

-

Test with 20°C pure water (not contained water) kinematic viscosity 1mm²/s.

-

Pump use refers to the performance range of thick lines to prevent the motor from too small a flow to produce overheating and too big a flow to produce overload.

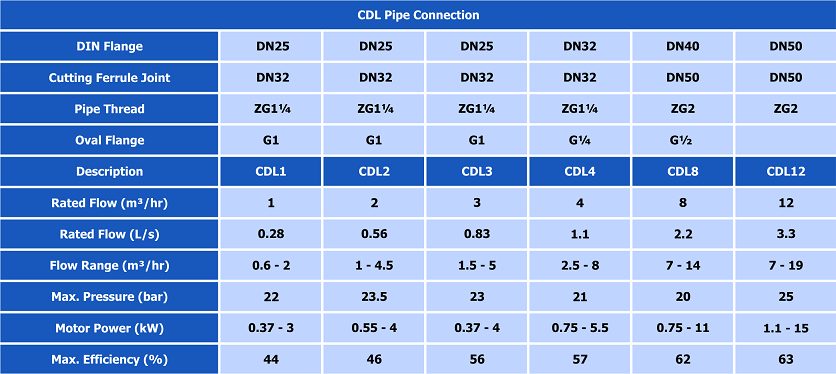

Technical data:

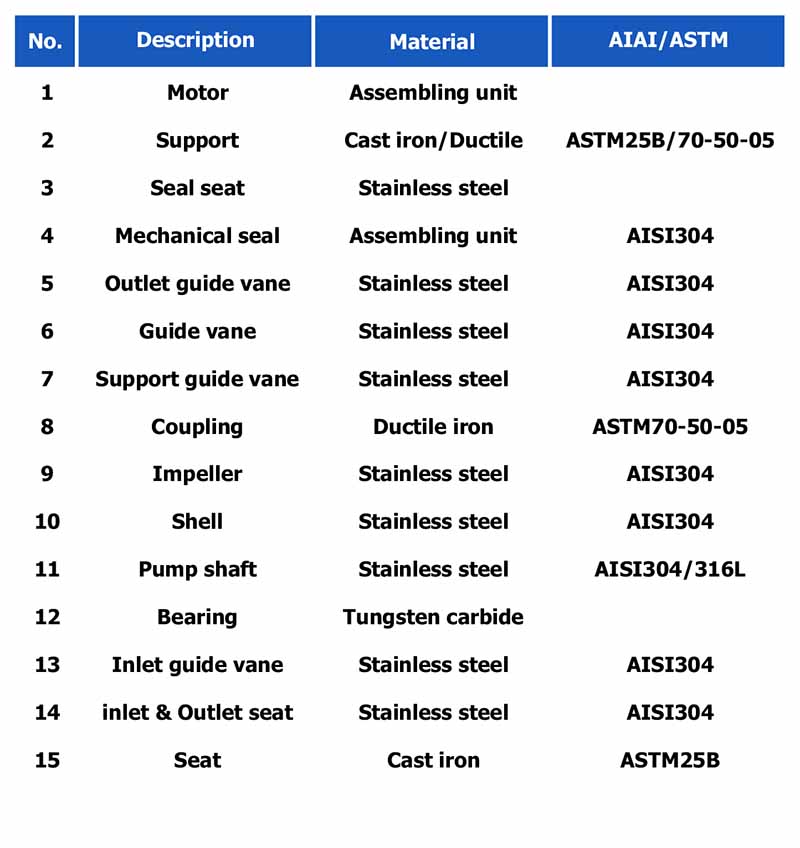

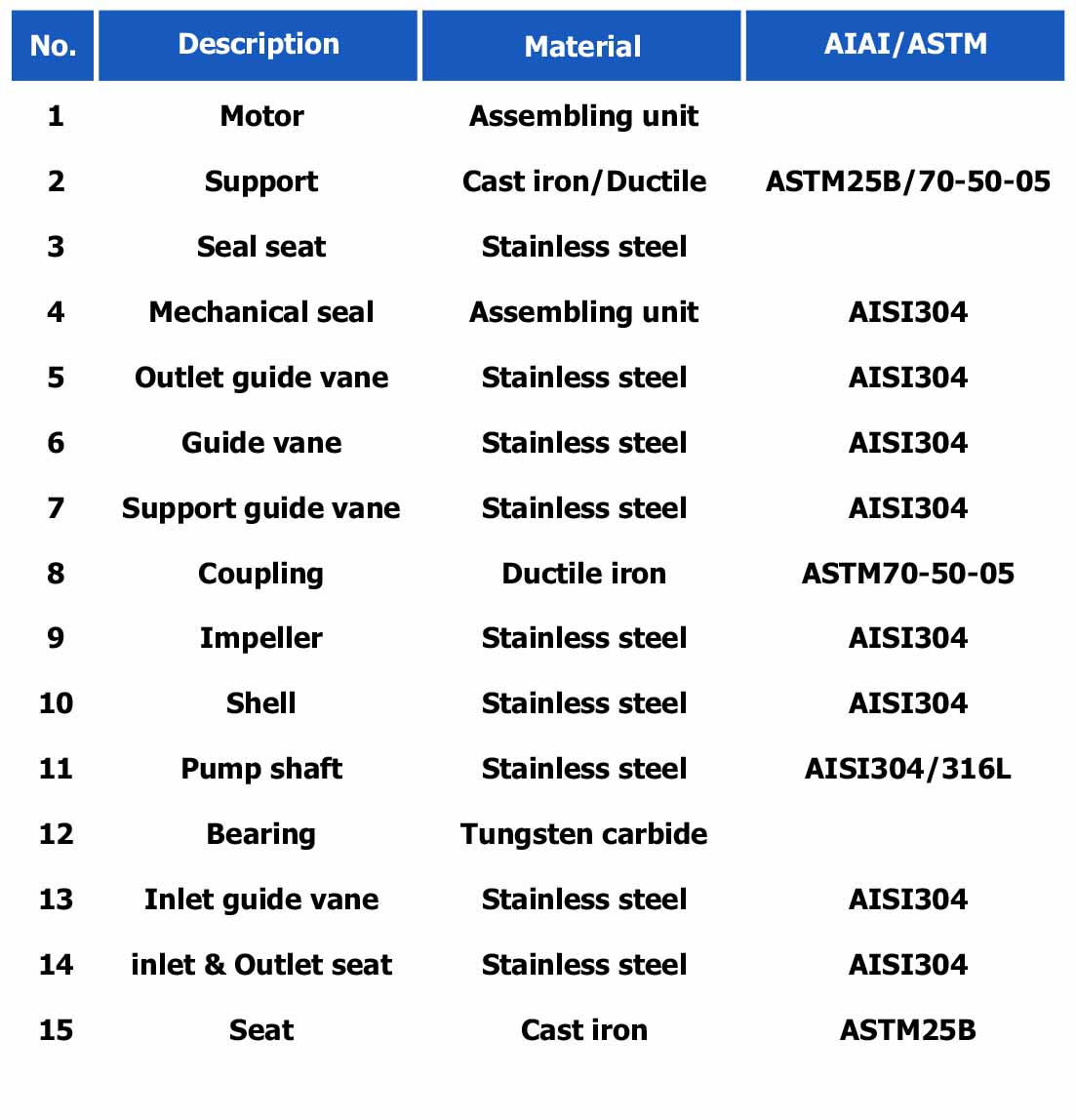

Material: CDL 1, 2, 3, 4

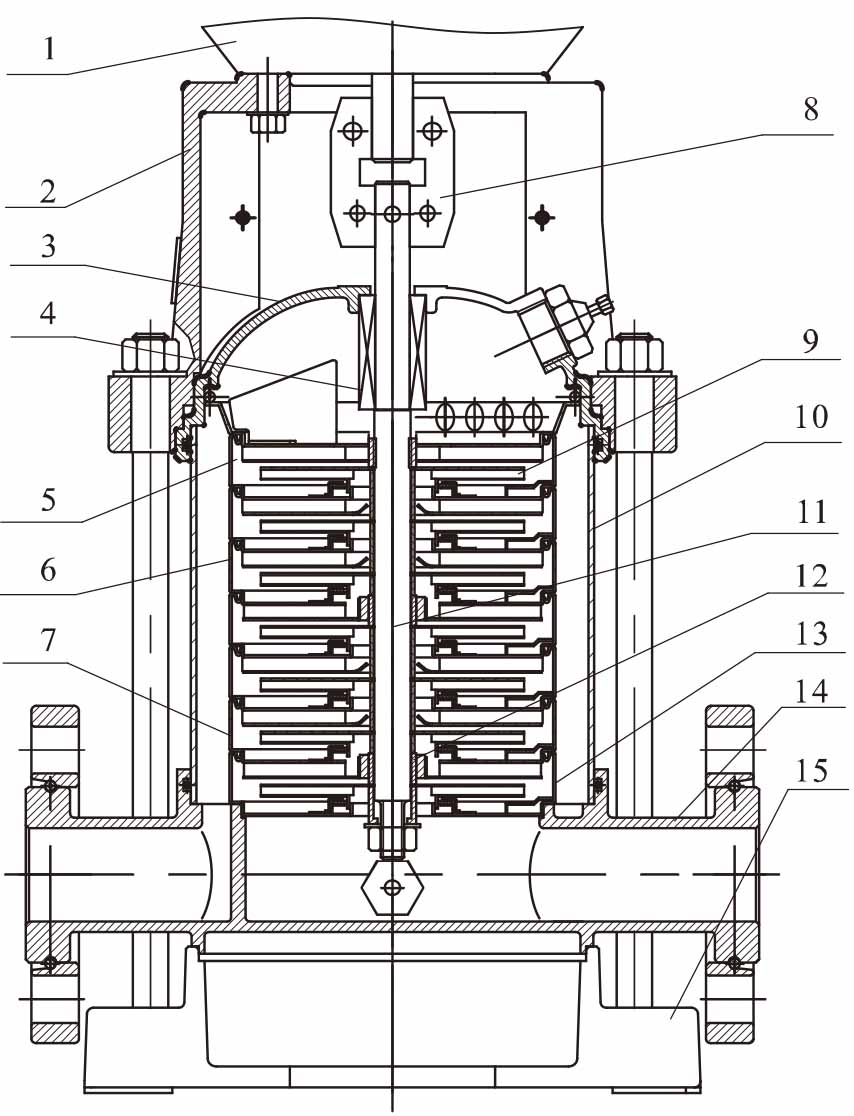

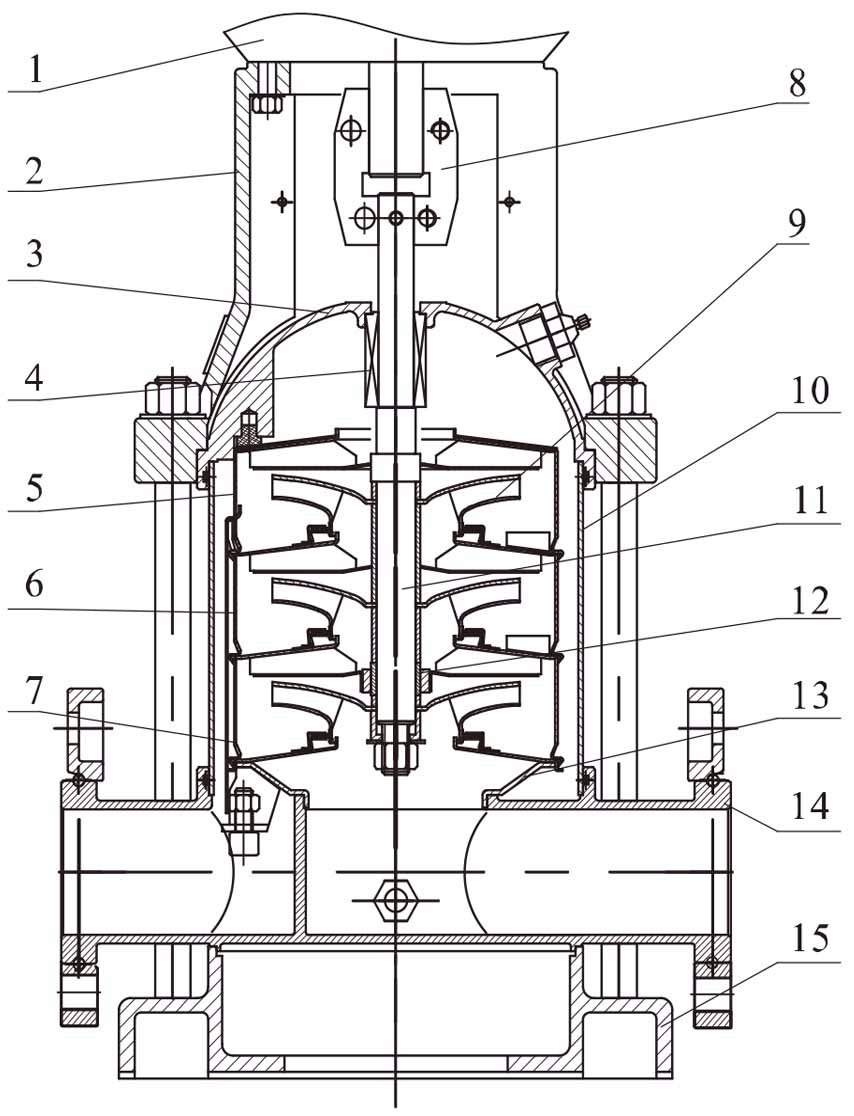

Structure chart: CDL 1, 2, 3, 4

Instruction

-

CDL is a non-self-priming vertical multi-stage pump and with a standard motor, the motor shaft and pump shaft are connected directly by coupling, and fitting the shell and flow passage components between the frame and inlet & outlet seat by pull rod and nuts. The inlet and outlet are in the same level line at the bottom of the pump.

-

The pump can be configured with an intelligent protector according to the need, to protect the pump from the dry run, lack of phase, overload, and so on.

Working condition

-

Thin, clean. non-flammable and explosive, and not containing solid particles or fiber liquids.

-

Liquid temperature: Room temperature: 15°C, +70°C.

-

Hot water: 15°C, ±105°C.

-

Environment temperature: Max. 40°C.

Specification:

Material: CDL 8, 12, 16, 20

Structure chart: CDL 8, 12, 16, 20

Specification:

.jpg)